Unveiling the Potential of Silicone Membrane SM-55 Grey

In today’s fast-paced industrial environment, the demand for high-quality materials is ever-increasing. Among these, the silicone membrane SM-55 grey has emerged as a frontrunner due to its remarkable properties and versatile applications. At silicone-membranes.eu, we offer a deep dive into why this material is a game-changer for various industries.

What is Silicone Membrane SM-55 Grey?

The silicone membrane SM-55 grey is a type of silicone rubber designed specifically for a range of demanding applications. This membrane delivers exceptional performance in environments requiring resilience, flexibility, and durability. Its unique formulation ensures that it remains stable across a wide range of temperatures, making it suitable for both high-temperature and low-temperature applications.

Key Features of Silicone Membrane SM-55 Grey

- High Resistance to Temperature: The SM-55 grey can withstand extreme temperatures, retaining its properties in both cold and warm conditions.

- Excellent Chemical Stability: This membrane is resistant to a wide array of chemicals, making it ideal for use in laboratories and industrial settings.

- Flexibility and Ease of Use: The membrane's design allows for easy installation and manipulation, reducing time and effort during project implementation.

- Durability: It boasts a longer lifespan compared to traditional membranes, reducing the frequency of replacements and maintenance costs.

- Non-Toxic and Safe: Made with materials that are safe for use in food and pharmaceutical applications.

Applications of Silicone Membrane SM-55 Grey

The versatility of silicone membrane SM-55 grey enables its use across various sectors. Here are some of the most popular applications:

1. Automotive Industry

In the automotive sector, the SM-55 grey is widely employed for air and liquid sealing applications. Its ability to withstand extreme conditions ensures reliable performance in vehicles.

2. Medical Devices

Due to its non-toxic nature, this silicone membrane is ideal for medical devices, providing reliable seals that prevent contamination while maintaining sterility.

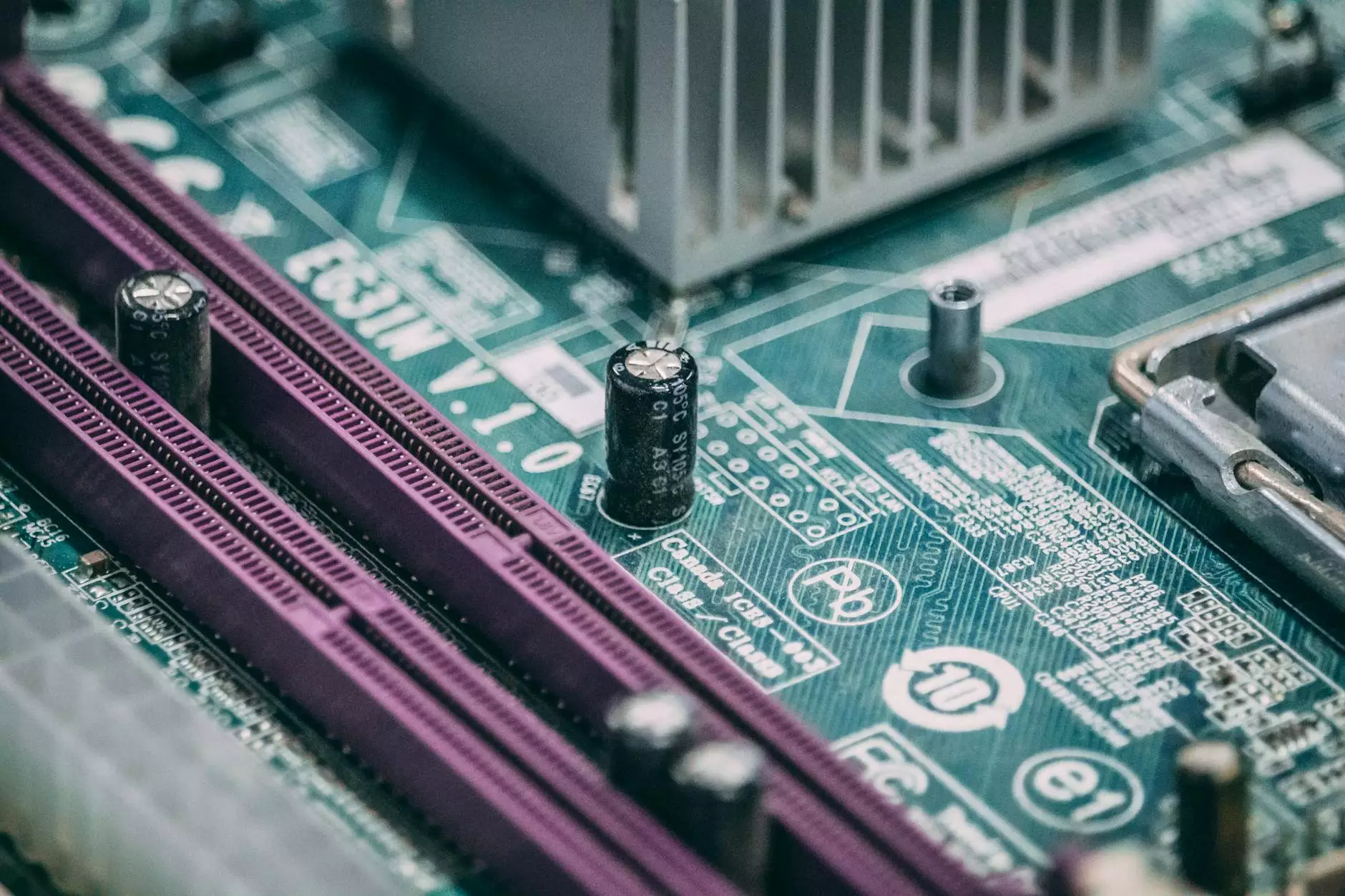

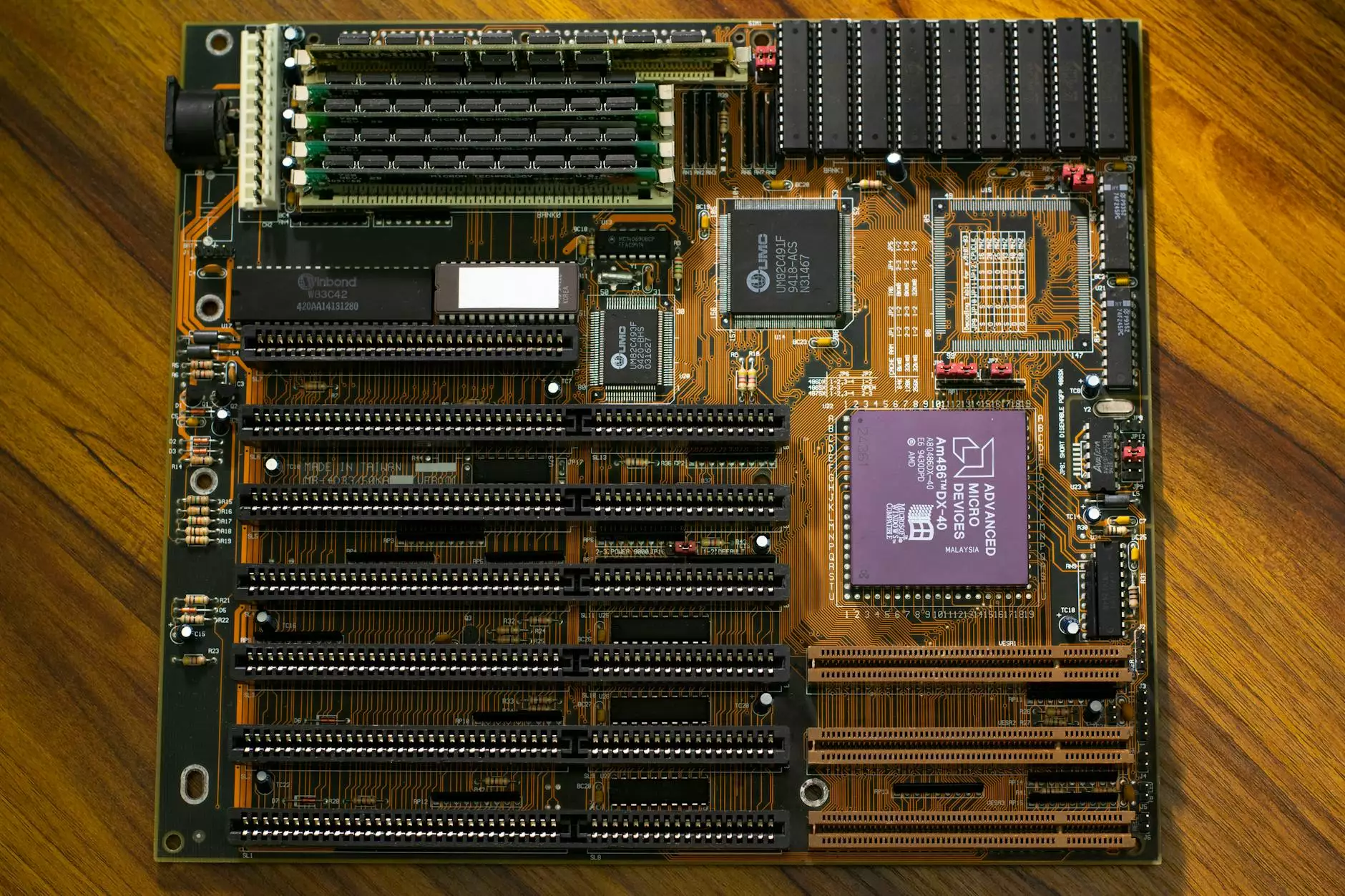

3. Electronics

In electronics, the need for effective sealing solutions is critical. The SM-55 grey membrane is regularly used in protecting sensitive components against moisture and dust.

4. Construction

In construction, the membrane can be utilized in various applications, including roofing materials, waterproofing, and sealing joints to enhance the lifespan of structures.

Why Choose Silicone Membrane SM-55 Grey?

Choosing the silicone membrane SM-55 grey for your projects can provide several key advantages:

Cost-Effectiveness

Despite being a premium product, the durability and longevity of the SM-55 grey membrane translate into significant cost savings over time. Reduced replacement and maintenance rates contribute to lower overall expenditures.

Enhanced Performance

The high-performance characteristics of this silicone membrane ensure that it can fulfill the demanding requirements of various applications without failure. This performance consistency translates into peace of mind for users.

Eco-Friendly Option

With increasing environmental concerns, the silicone membrane SM-55 grey stands out as an eco-friendly choice. Its production and disposal processes have a lower environmental impact compared to many alternative materials.

How to Properly Install Silicone Membrane SM-55 Grey

Successful implementation of the SM-55 grey membrane hinges on proper installation techniques. Here’s a step-by-step guide to ensure optimal results:

Step 1: Surface Preparation

Make sure the surface where the membrane will be installed is clean, dry, and free from debris. This will enhance adhesion and ensure a tighter seal.

Step 2: Measuring and Cutting

Measure the desired dimensions carefully and cut the silicone membrane accordingly. Precision is key, as any miscalculation can lead to unnecessary waste and increased costs.

Step 3: Apply Adhesive

Select a silicone-compatible adhesive and apply it evenly on both the membrane and the substrate surface. Follow the manufacturer’s instructions for optimal curing times.

Step 4: Positioning the Membrane

Carefully position the membrane on the surface, ensuring it aligns perfectly with the intended area. Press down firmly to establish a solid bond.

Step 5: Final Assessment

After installation, perform a comprehensive check to ensure there are no gaps or weak spots. This final verification is essential for long-lasting performance.

Maintenance and Care of Silicone Membrane SM-55 Grey

To prolong the life of your silicone membrane SM-55 grey, consider the following maintenance tips:

- Regularly inspect for any signs of wear or damage.

- Clean the surface using non-abrasive cleaning solutions to avoid degrading the material.

- Ensure that the installation area is kept free of sharp objects that could puncture or tear the membrane.

Conclusion

In conclusion, the silicone membrane SM-55 grey is an invaluable asset across various industries. Its unique properties, combined with its versatility, make it a prime choice for those looking for reliability and performance in materials. By opting for the SM-55 grey, you are investing in a product that not only meets but exceeds expectations in various applications.

For more detailed information and to purchase the silicone membrane SM-55 grey, visit silicone-membranes.eu. Elevate your projects and experience the benefits of premium silicone membranes today!