Bottle Label Applicators: Revolutionizing Product Packaging

In the fast-paced world of business, especially within the Printing Services and Electronics sectors, efficiency and precision are paramount. One of the key elements that businesses must focus on is their packaging, which includes the application of labels. This is where the bottle label applicator comes into play, transforming the conventional processes associated with labeling into an art of precision and speed.

What is a Bottle Label Applicator?

A bottle label applicator is a specialized device designed to apply labels to bottles with remarkable accuracy. These machines can cater to a wide range of bottle types, including plastic, glass, and metal, used in various industries like beverages, cosmetics, and pharmaceuticals. The effectiveness of the applicator not only speeds up the labeling process but also enhances the overall visual appeal and professionalism of the product.

The Importance of Accurate Labeling

Labeling is a crucial aspect of any product. Here’s why:

- Brand Identity: Labels carry the brand logo and information, making it essential for brand recognition.

- Legal Compliance: Many products are required by law to have specific information on their labels, including ingredient lists, warnings, and usage instructions.

- Consumer Information: Quality labels inform customers about the product, enhancing their purchasing decision.

Advantages of Using a Bottle Label Applicator

Choosing to invest in a bottle label applicator provides numerous advantages for businesses:

1. Enhanced Efficiency

Manual labeling can be time-consuming and prone to errors. A bottle label applicator streamlines this process, allowing businesses to label thousands of bottles in a fraction of the time it would take manually.

2. Consistency and Precision

The machine ensures that each label is applied in the same position with identical orientation, giving your products a uniform look that signifies quality.

3. Cost-Effective

Although an upfront investment is necessary, the long-term savings from reduced labor costs and increased production speed can be substantial. Businesses can also reduce waste due to fewer misapplied labels.

4. Versatility

Modern bottle label applicators are designed to be versatile, suitable for various bottle shapes, sizes, and materials. This adaptability makes them an ideal choice for small or large production runs.

Types of Bottle Label Applicators

Understanding the different types of bottle label applicators can help businesses select the right one for their needs:

1. Manual Applicators

These are ideal for small businesses or startups. They require an operator to apply the labels manually, which can be effective for low-volume runs.

2. Semi-Automatic Applicators

Semi-automatic machines allow the operator to place the bottle while the machine applies the label. This is perfect for medium-sized businesses looking to increase efficiency without a massive investment.

3. Fully Automatic Applicators

For high-volume production environments, fully automatic applicators can manage the entire labeling process without human intervention, making them the most efficient option.

How to Choose the Right Bottle Label Applicator

When selecting a bottle label applicator, consider the following factors:

1. Production Volume

Assess your production needs. High-volume operations may benefit from fully automatic models, while smaller businesses could start with manual or semi-automatic devices.

2. Bottle Specifications

Ensure the machine can handle the sizes and shapes of your bottles. Check compatibility with various materials such as glass, plastic, or metal.

3. Label Size and Material

The width and length of your labels as well as their adhesive properties are crucial in determining the correct applicator.

4. Budget

Consider your budget not only for the initial purchase but also for ongoing maintenance and potential repairs.

Innovative Features of Modern Bottle Label Applicators

Modern bottle label applicators come equipped with a variety of innovative features that enhance their efficiency:

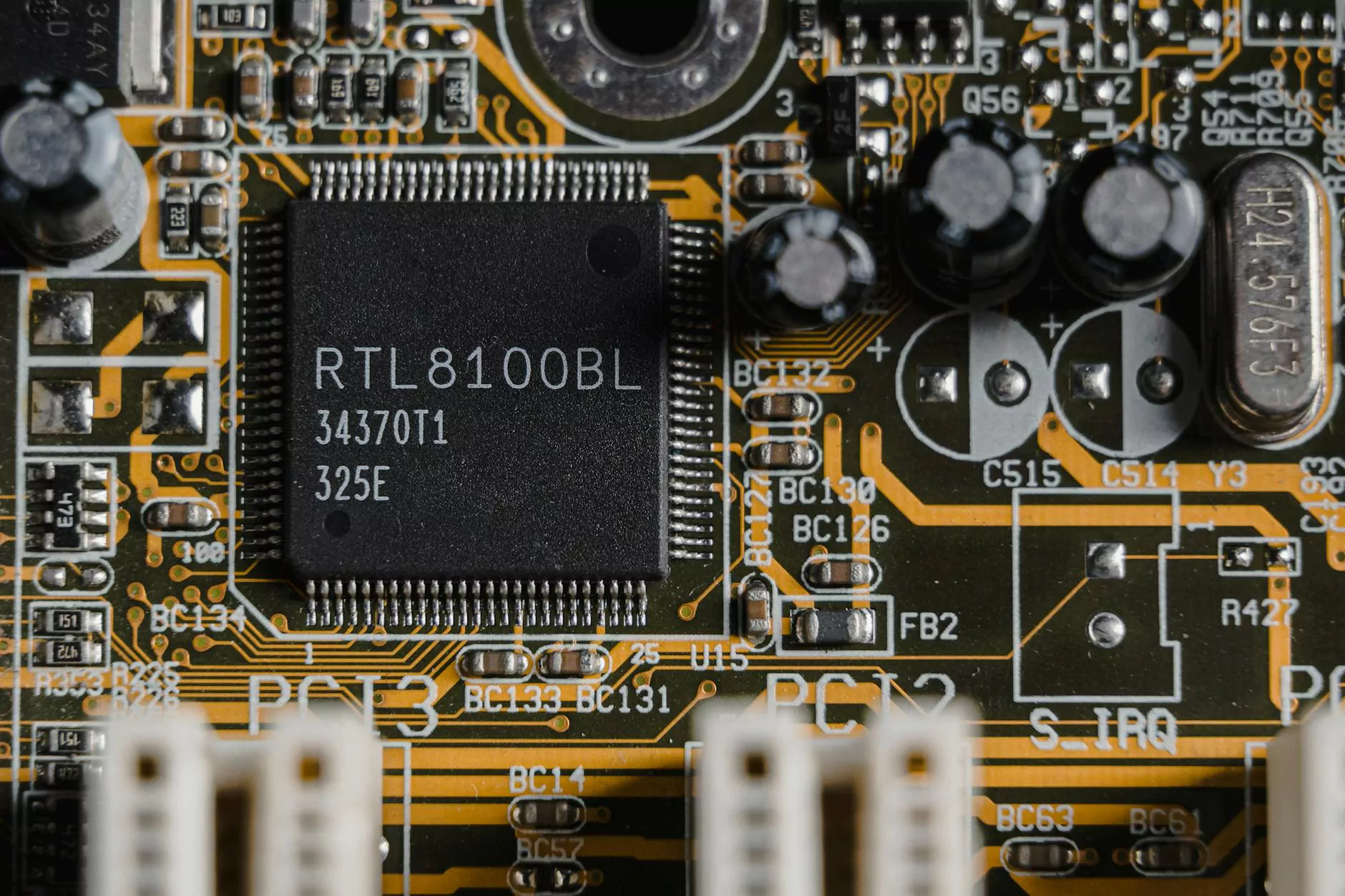

1. Smart Technology Integration

Many new models offer advanced technology that monitors labeling processes, providing real-time data that can enhance productivity.

2. Easy Adjustment Settings

Modern machines allow for quick adjustments to accommodate different bottle shapes and sizes, making changeovers simple and efficient.

3. High-Speed Labeling Capabilities

Today's bottle label applicators can operate at significantly higher speeds than earlier models, helping businesses meet increasing production demands.

Case Studies: Successful Implementation of Bottle Label Applicators

Many businesses have greatly benefited from integrating bottle label applicators into their operations:

1. Beverage Industry

A prominent beverage company transitioned from manual labeling to a fully automatic bottle label applicator, resulting in a 50% increase in productivity. This shift allowed them to reduce costs and reallocate labor to other areas of production.

2. Cosmetics Sector

A cosmetics manufacturer adopted a semi-automatic bottle label applicator to enhance their product presentation. The consistent labeling improved brand identity and helped boost sales by 30% within the first quarter.

Conclusion

In a competitive marketplace, investing in a bottle label applicator can provide businesses with a significant edge. With enhanced efficiency, consistency, and precision, these machines are essential for any operation that deals with bottled products. At Omega Brand, we understand the importance of effective labeling solutions for businesses in the Printing Services, Electronics, and Computers sectors. Our range of state-of-the-art bottle label applicators is designed to help businesses achieve their labeling goals while ensuring top-notch quality and reliability.

Whether you're a small startup or an established enterprise, exploring the options available in bottle label applicators can lead you to improved productivity and success. Let Omega Brand assist you in choosing the perfect labeling machine to meet your unique requirements.