Transforming Manufacturing with 5 Axis CNC Routers from China

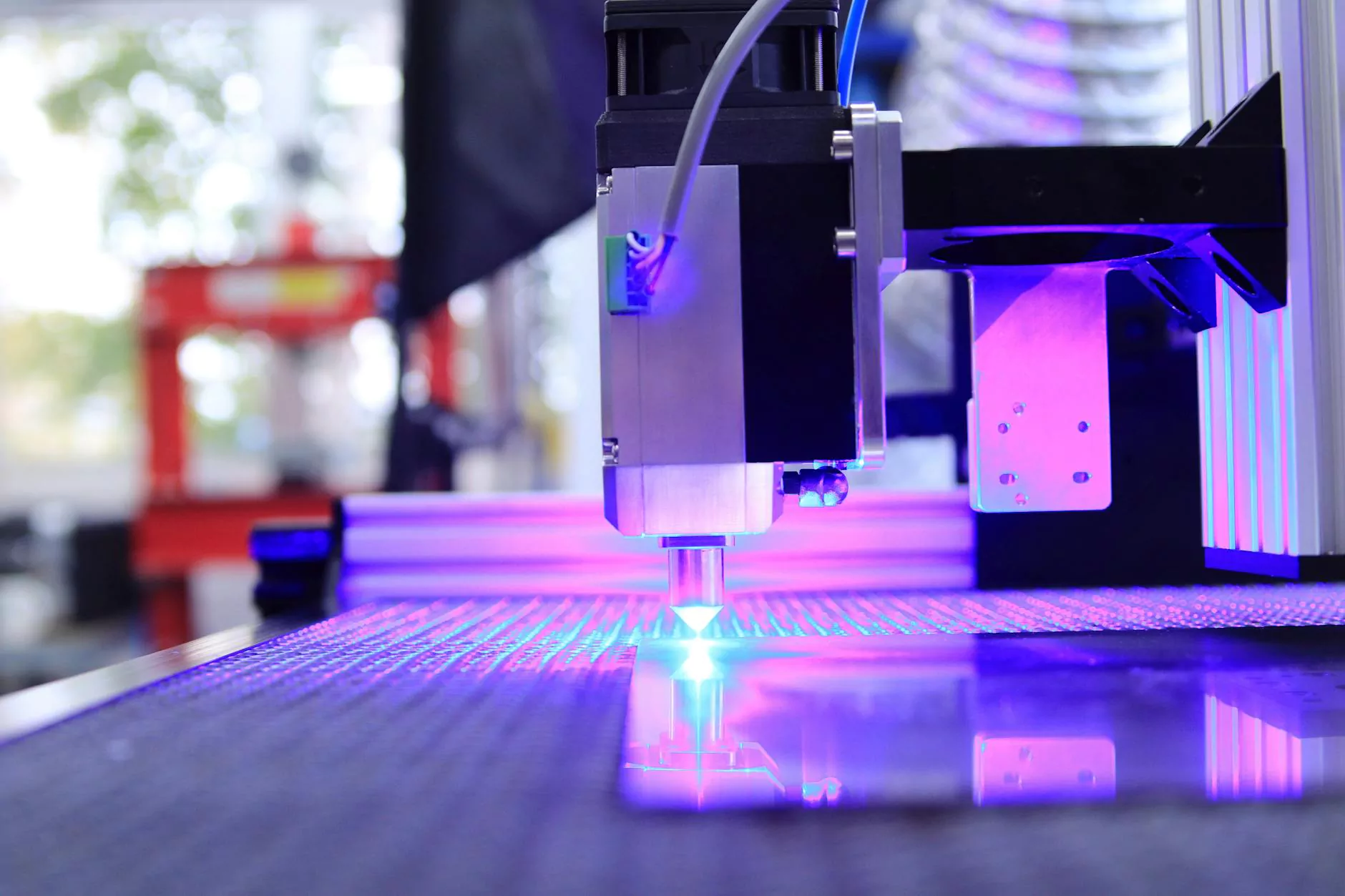

The manufacturing landscape has undergone a significant transformation over the past few decades, primarily owing to technological advancements. Among the critical innovations in this domain is the introduction of 5 axis CNC routers, particularly emerging from China. These machines not only enhance precision but also redefine manufacturing processes, enabling businesses to innovate and thrive. In this article, we will delve deep into the various facets of 5 axis CNC routers made in China, their benefits, applications, and why they are an excellent choice for enterprises looking to maximize efficiency and productivity.

What are 5 Axis CNC Routers?

5 axis CNC routers are state-of-the-art tools capable of executing complex machining tasks with greater precision than their 3 axis counterparts. The term “5 axis” refers to the machine's ability to move its cutting tool or workpiece in five different axes simultaneously, allowing for intricate cuts and shaping that were once thought impossible.

- Axis 1: The X-axis (horizontal movement).

- Axis 2: The Y-axis (vertical movement).

- Axis 3: The Z-axis (depth movement).

- Axis 4: Rotation around the X-axis.

- Axis 5: Rotation around the Y-axis.

This unique configuration allows for multi-dimensional corrections, enabling manufacturers to create intricate designs in materials such as wood, metal, plastics, and composite materials. As a result, businesses that utilize these advanced machines experience substantial improvements in productivity and quality.

Benefits of 5 Axis CNC Routers from China

When considering a purchase of a CNC machine, particularly a 5 axis router, there are several compelling reasons to opt for those manufactured in China:

1. Cost-Effectiveness

Chinese manufacturers are known for their competitive pricing. The cost of 5 axis CNC routers produced in China is often significantly lower than similar machines from Western manufacturers. This is attributed to lower labor costs and a robust supply chain network that keeps production expenses in check.

2. Advanced Technology and Innovation

China's commitment to technological advancement is evident in its CNC machines. The integration of automation, IoT, and smart technology enhances the functionality and efficiency of these machines, making them suitable for modern manufacturing challenges.

3. Versatile Applications

5 axis CNC routers are used across various industries, including:

- Aerospace: Precision parts manufacturing.

- Automotive: Component production and prototyping.

- Woodworking: Furniture design and decor.

- Sign-Making: Customized signage solutions.

- Medical: Fabrication of surgical instruments and implants.

This versatility makes them an excellent investment for companies aiming to diversify their offerings and improve production capabilities.

How to Choose the Right 5 Axis CNC Router

Choosing the right 5 axis CNC router from China involves several considerations:

1. Understand Your Requirements

Before making a purchase, it’s vital to evaluate your specific needs. Consider the types of materials you will be working with, the complexity of projects, and the desired production volume. This understanding will guide you in selecting a machine with appropriate specifications.

2. Assess Machine Specifications

Look for technical specifications such as:

- Work table size

- Spindle power and speed

- Maximum cutting thickness

- Control system type and software compatibility

These factors will significantly impact your machine's performance and effectiveness in your manufacturing processes.

3. Supplier Reputation

Research potential suppliers thoroughly. Look for reviews, testimonials, and case studies that highlight their previous work with companies similar to yours. A solid reputation often correlates with the quality of machines produced and the support offered.

4. After-Sales Support and Service

Ensure that the manufacturer provides comprehensive after-sales support. This includes installation, training, and maintenance services. A reliable support system ensures your operations run smoothly without prolonged downtime due to equipment issues.

Real-World Applications of 5 Axis CNC Routers

To appreciate the capabilities of 5 axis CNC routers, it’s essential to look at some real-world applications:

1. Aerospace Industry

In the aerospace sector, precision is paramount. 5 axis CNC routers are utilized to create complex geometries required for aircraft components. Their ability to cut intricate shapes results in lightweight and structurally sound parts, which are essential for aircraft performance and safety.

2. Automotive Manufacturing

For the automotive industry, these routers offer the ability to manufacture components such as engine houses and body parts with exceptional accuracy. This efficiency translates into shorter production times and reduced labor costs, ultimately boosting profitability.

3. Architectural Design

Architects and designers leverage the precision of 5 axis CNC routers to create bespoke furniture and intricate architectural details. Clients are increasingly demanding unique designs, and these machines enable the realization of such visions quickly and accurately.

4. Custom Signage

Sign makers are adopting 5 axis routers to produce custom signs with unique shapes and dimensions. The ability to work with various materials, including wood and metal, enhances the artistic options available for sign-making.

The Future of 5 Axis CNC Routers

The future of 5 axis CNC routers looks bright. As industries continue to demand greater precision and efficiency, advancements in technology—such as Artificial Intelligence (AI) and machine learning—are likely to enhance the capabilities of these machines further. Here are some trends to watch:

1. Enhanced Automation

Automation is a growing trend in manufacturing. The integration of AI will allow CNC routers to optimize machining paths and reduce waste, further increasing productivity.

2. Smart Manufacturing

With the rise of the Internet of Things (IoT), 5 axis CNC routers can be connected to networked systems, providing real-time data on machine performance and maintenance schedules. This capability leads to improved decision-making and operational efficiency.

3. Sustainability

As businesses strive for sustainability, advancements in CNC technology are enabling more efficient material use, reducing waste significantly. Manufacturers are also exploring eco-friendly materials, further aligning production processes with environmental goals.

Conclusion: Investing in 5 Axis CNC Routers from China

In summary, 5 axis CNC routers from China represent a pivotal investment for manufacturing enterprises aiming to enhance their competitiveness. The blend of affordability, advanced technology, and versatility makes these machines an attractive option for various industries. By carefully assessing your needs, choosing a reputable supplier, and understanding the extensive applications of these routers, your business can significantly improve productivity, reduce costs, and innovate in ways previously thought impossible.

For more information on quality CNC machines for sale, explore our offerings at roc-tech.com and discover how we can help elevate your manufacturing processes!

5 axis cnc routers china